Modern Rice Milling Process Steps & Paddy Rice Milling Systems Flowchart

Rice milling in modern age is the combination of several commercial milling operations that produce better quality white rice from rough rice (Rice Paddy).

Table of Contents

Modern Rice Milling Processes

Milled Rice is being produced, in Rice mills, after removing bran, husk and germ. Rice produced after modern rice milling process has different flavor, appearance ( whiten) and extended life.

Would not you want to know more about this modern rice milling?

What is Rice Milling ?

Rice milling process is all about producing edible milled rice after separating the husk (20%), the bran layers (11% ) & clean rice (69%) aka starchy endosperm.

In an ideal milling process this will result in 20% husk, 8−12% bran depending on the milling degree and 68−72% milled rice or white rice depending on the variety.

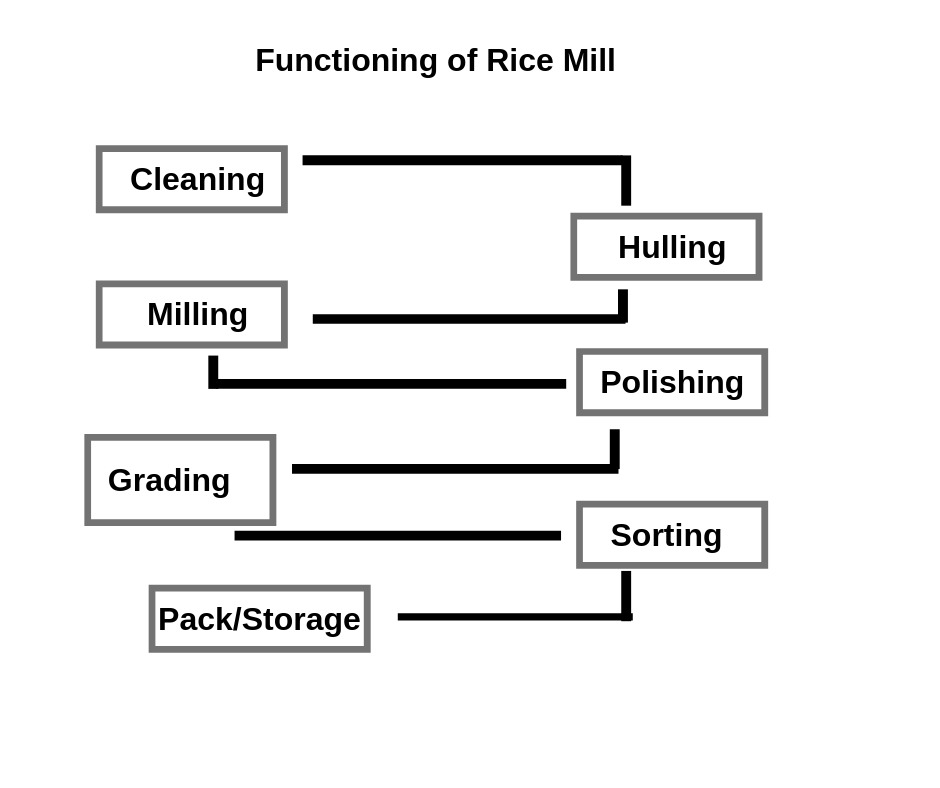

Modern Rice Milling flow chart

Let’s discuss rice mill functioning and steps in rice milling processes from pre-cleaning to packaging for sale.

Rice Pre-cleaning Process

Paddy Rice cleaning process also called rice paddy cleaning process. It is first step in rice milling systems after rice paddy comes for milling process in rice mill from Rice farms.

Paddy always comes up having a lot of external material including weed, soil, seeds, etc. And these external things need to be removed before taking it to the hulling processes, so that the efficiency of the huller, as well as milling, would not get affected.

If they are not removed properly then the efficiency of the rice mill machinery can be reduced. The capacity of the paddy pre-cleaner is actually, 1.5 times the milling capacity. It makes rice milling an ideal in this modern age.

Rice Cleaning Process

Removing the husk (dehusking or dehulling)

Brown rice is actually produced by removing the husk from rough paddy rice. The husk is actually removed using friction so that paddy grains can easily pass in between two abrasive surfaces that move following different speeds.

It makes easy to let husk removed following suction and transported to a storage dump outside the mill. It means you would not have to confront a lot of hassle anymore.

Paddy separation

Paddy separator is good at unhusked paddy rice from brown rice making easier to go ahead with the next procedure in modern rice milling systems.

Talking about the amount of paddy actually depends on different thing including the efficiency of the husker and it should not be more than 10%. Paddy separators work in a great way making the entire procedure easier and smooth.

Whitening or Polishing

Do you know that how whitening or polishing rich are made? Here, we are going to talk about rice whitening process in modern rice mill.

Actually, white rice is produced removing the bran layer and then germ from the paddy. Now, you might be thinking that how does bran layer is removed. To put in simple words, the bran layer is removed from the kernel going with the different policies such as abrasive or friction polishers. The amount of bran removed is normally between 8 and 10% of the total paddy weight.

Separation of white rice

and the next on the list is all about separation of white rice. Once rice polishing is done, white rice is separated into head rice, small, broken and large rice.

Head rice is generally categorized as Kernels having ration of 75-80o or more of a whole kernel. In order to have a higher degree of precision for grading and separation a length or indent grader is used.

Rice mixing

Talking about a good modern age rice mill, it generally produced 50−60%

- Head rice (whole kernels),

- 5−10% large broken

- 10−15% small broken kernels

Moreover, it also depends on country standards as well as what is all about the rice grades in the market as it will contain from 5−25% broken kernels. If rice mixing is get done in a sophisticated manner then a volumetric mixer is necessary.

Mist polishing

It is all about mixing a fine mist of water having dust retained on the whitened rice in order to improve the luster of rice. The motto is not compromising with the quality of rice. A friction type of whitening machine plays a major role to deliver a fine mist of water during the final whitening process ideal for “final” polishing before the sale.

Rice weighing

Now, it is time to know about rice weighing. To put in simple words, rice is normally sold in 50 kg sacks and it should be weight accurately and labeled. These days, most rice mills are preferring to go with the advanced manual mechanical weighing system, so that they can have accurate results. This fast electronic system is considered ideal to go ahead.

To make more profit, it is needed to make sure that you are going to have advanced machinery at your work to gain amazing results in rice milling operations.