Power Up Your Rice Production: The Best Rice Hullers for Every Need

Table of Contents

Everything about Rice Huller / Rice Husker

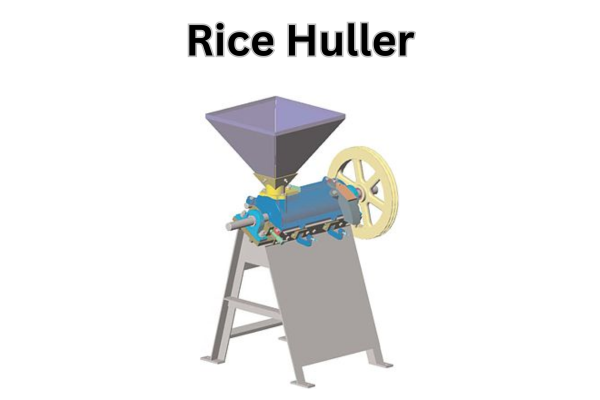

What is a rice huller?

A rice huller, also known as a rice husker, is a machine used to remove the outer husk of paddy rice grains. This process is called hulling or husking. Paddy rice is the unmilled form of rice, with the husk still intact. Brown rice is produced by removing the husk only, while white rice is produced by removing the husk and bran layer.

History of rice hulling

Rice has been cultivated for over 5,000 years, and hulling has been an essential part of the process of preparing it for consumption for much of that time. Traditionally, rice was hulled by hand using a mortar and pestle or a stone mill. These methods were labor-intensive and produced a lot of broken rice.

Different Types of Rice Hullers: From Emery Discs to Cono Wonders

From humble beginnings to industrial efficiency, the path of a paddy rice grain is paved with different types of rice hullers, each with its own personality and purpose. Let’s dive into the world of rice dehusking:

1. Hand-operated Hullers

Think mortar and pestle: Imagine rhythmic pounding, a timeless tradition, and the satisfaction of transforming rice with sheer muscle. Simple, effective, and deeply connected to heritage.

Perfect for: Small-scale processing, savoring brown rice’s nutritional benefits, and adding a touch of history to every bite.

Drawbacks: Labor-intensive, slow process, potentially higher grain breakage.

2. Pedal-operated Hullers

Step up the power: These hullers harness the rhythm of your legs, offering efficiency without sacrificing the charm of manual operation. Think treadle designs or bicycle-inspired models.

Ideal for: Moderate-scale processing, finding a balance between effort and output, and enjoying a workout with your rice harvest.

Drawbacks: Still requires physical exertion, may not be suitable for everyone’s fitness level.

3. Motorized Hullers

Electric revolution: Plug in and let the machine do the hard work! From compact personal-use options to industrial giants, motorized hullers deliver efficiency and ease.

Perfect for: Efficient processing, higher output with minimal physical effort, and catering to all processing needs.

Drawbacks: Higher initial cost and dependence on electricity, potential for noise and maintenance.

4. Pneumatic Hullers

Air-powered powerhouse: These cutting-edge machines utilize compressed air for lightning-fast hulling. They offer exceptional output and minimal grain breakage, making them ideal for large-scale production.

Ideal for: Industrial-level processing, achieving maximum efficiency and output for commercial needs.

Drawbacks: Highest initial cost, complex operation and maintenance, requires access to compressed air.

How does a rice huller work?

The process of hulling rice with a rice huller typically involves the following steps:

- Paddy rice is fed into the hopper of the rice huller.

- The paddy rice is then passed between abrasive discs or rollers, which remove the husk.

- The husk is separated from the brown rice and is usually collected in a separate bin.

- The brown rice is then polished to remove the bran layer and produce white rice (optional).

Factors to consider when choosing a rice huller

If you are considering buying a rice huller, there are a few factors to consider, such as:

- The size of your operation: If you only need to hull rice for your own personal use, a small, manual rice huller will suffice. However, if you are hulling rice for commercial purposes, you will need a larger, more powerful machine.

- The type of rice you are hulling: Different types of rice have different hulling requirements. For example, long-grain rice is more difficult to hull than short-grain rice.

- Your budget: Rice hullers can range in price from a few hundred dollars to tens of thousands of dollars.

Rice hullers are an essential piece of equipment for anyone who wants to produce brown or white rice. By understanding the different types of rice hullers available and the factors to consider when choosing one, you can choose the right machine for your needs.

FAQs about Rice Huller

Paddy husking aims to eliminate rough rice shells, preparing it for brown rice. Friction between paddy grains and two moving abrasive surfaces achieves husk removal.

In the rice hulling process, paddy undergoes squeezing, rubbing, and tearing between two rubber rollers to remove the husk.

The rice husk, or rice hull, acts as a protective coating on a rice seed. Composed of hard materials like silica and lignin, it shields the seed during growth. Approximately 0.28 kg of rice husk is produced per kg of milled white rice during milling.

Traditionally cultivated scented and basmati rice exhibit hulling percentages ranging from 72% to 82%.

During the composting of raw rice husk, the pH decreases from 7.1 to 6.1 due to organic acid production. Subsequently, it rises to 8.6 during the thermophilic period.