Why 1121 Rice Rolls are Ideal for High-Quality Rice Production

In a world where high-quality rice is in high demand, rice producers are constantly striving to meet the expectations of discerning consumers. One such rice variety that has gained significant popularity is the 1121 rice roll. In this blog post, we will delve into the reasons why 1121 rice rolls are considered ideal for high-quality […]

Role of Controlled Paddy Dust During Rice Milling

Role of Controlled Paddy Dust During Rice Milling You know how when you’re milling rice, all that dust kicks up? Sure it makes a mess, but don’t go grabbing the broom just yet. Turns out that paddy dust isn’t just a nuisance – it can actually help make a better final product if managed properly. […]

Importance of Balancing Rice Rubber Rolls

The Importance of Balancing Rice Rubber Rolls Like Tyre You know that feeling when you get a new set of tires on your car and it feels like you’re floating on air? The ride is so smooth and quiet that you can’t believe the difference new rubber makes. Well, that same principle applies to the […]

Role of Controlled Moisture in Paddy During Dehusking

The Role of Controlled Moisture in Paddy During Dehusking Ever get frustrated trying to get that last bit of rice out of the husk? You know what I’m talking about – when you’re rinsing it and some grains stay stubbornly stuck. Well, my friend, you’ve come to the right place. In this article, we’ll explore […]

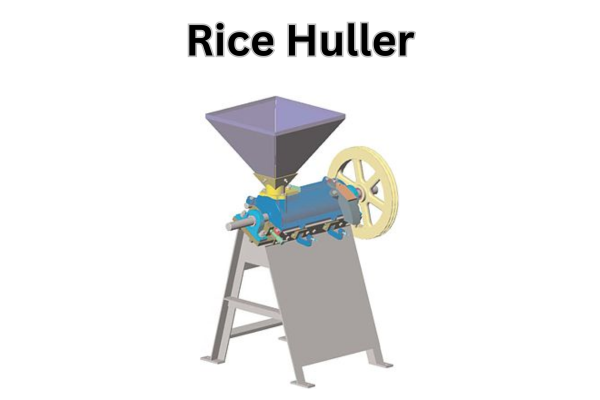

Power Up Your Rice Production: The Best Rice Hullers for Every Need

Everything about Rice Huller / Rice Husker What is a rice huller? A rice huller, also known as a rice husker, is a machine used to remove the outer husk of paddy rice grains. This process is called hulling or husking. Paddy rice is the unmilled form of rice, with the husk still intact. Brown […]

Modern Rice Milling Process Steps & Paddy Rice Milling Systems Flowchart

Rice milling in modern age is the combination of several commercial milling operations that produce better quality white rice from rough rice (Rice Paddy). Modern Rice Milling Processes Milled Rice is being produced, in Rice mills, after removing bran, husk and germ. Rice produced after modern rice milling process has different flavor, appearance ( whiten) and […]

Rice Mill Maintenance

Most important part of whole rice milling process is rice mill machine. It is a grain processing equipment. Regular maintenance of Rice mill machinery is needed to prolong service life of rice mill machines. Let’s briefly introduce the maintenance of rice mills or we can say rice milling machine( because machinery plays major roll in […]

Rice Mill Functioning Guide for Rice Milling Businesses

Rice Mill Functions Rice is the most Favorite and most widely used food world over and this blog covers the modern rice milling process as we very well know, Rice is a natural product and is produced by farming on land. Farming produces rice in the form of PADDY. Paddy Dehusking This paddy consists of […]